Full Service Machining - Pump Parts

With a staff of fully trained machinists, our machine shop is ready to fabricate your turbine pump parts, replace outdated and hard to find pump parts, or retrofit parts of a pumping system to your exact specifications. Our machine shop in Phoenix specializes in pump parts for all major OEM manufactures and makes of Pumps.

Our shop of fully staffed machinists will perform:

Bowl Assembly repair

Discharge head repair or retrofit

Repairing Tube & Shaft Assemblies

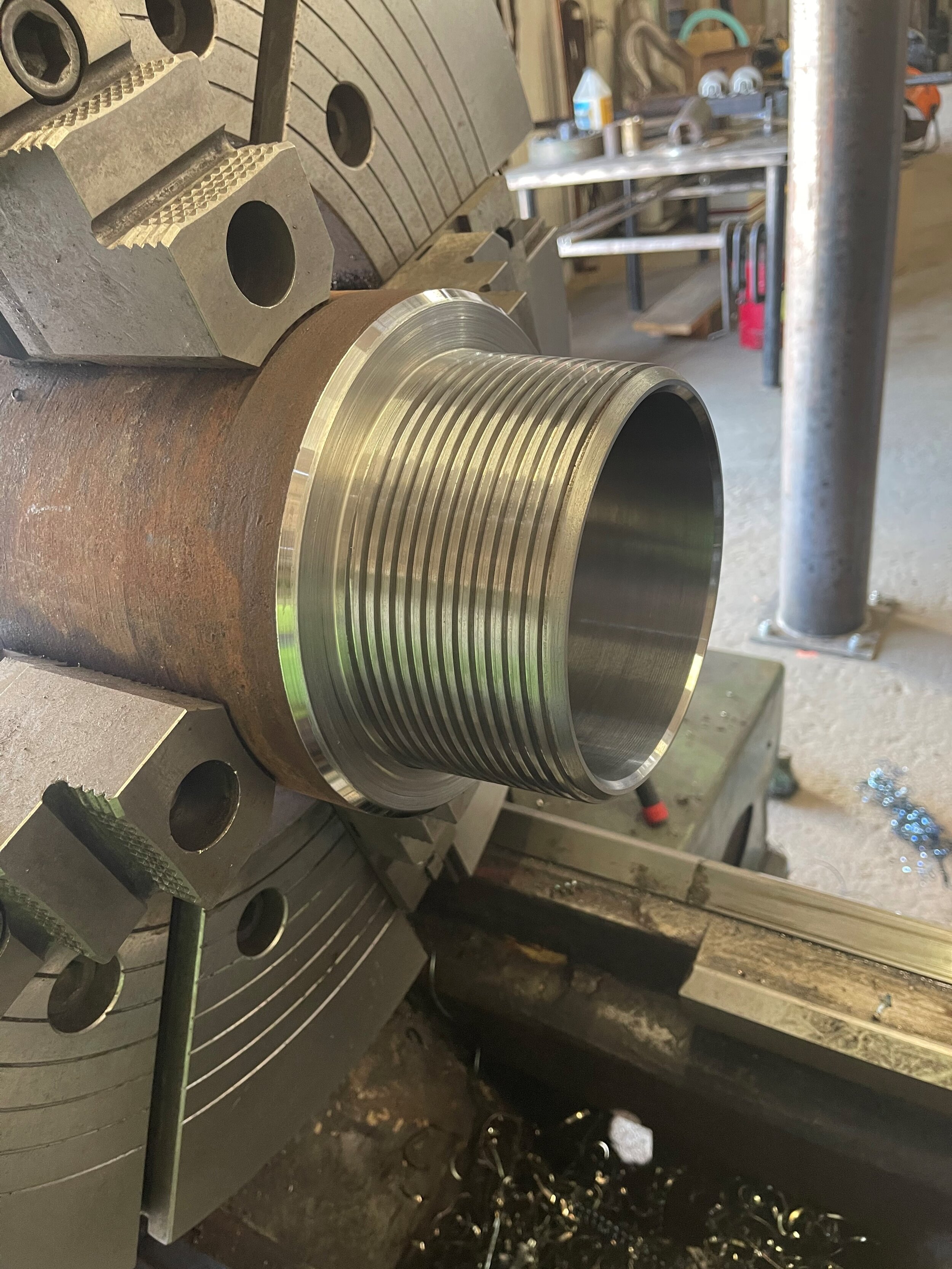

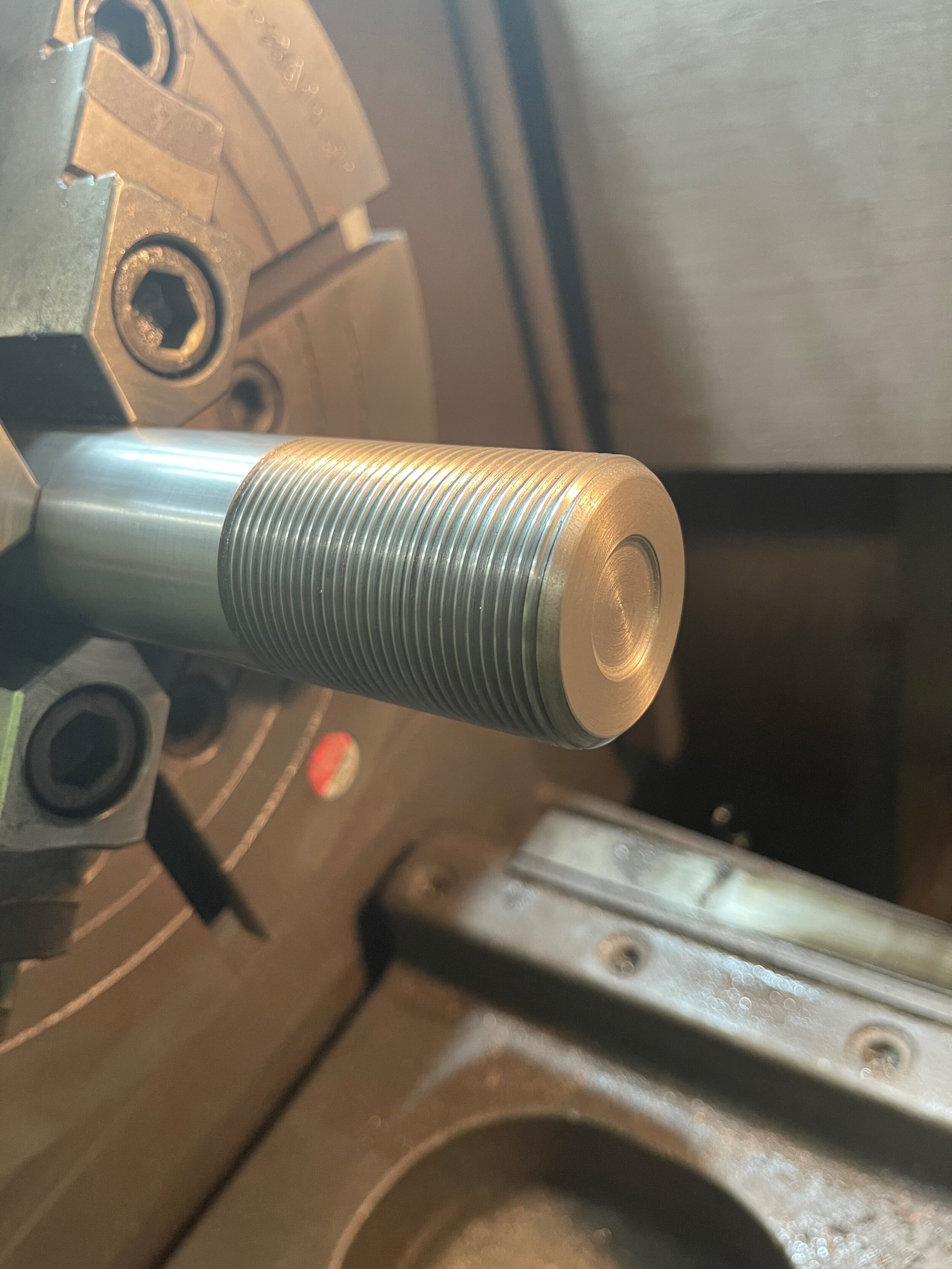

Turning and facing of all sizes and materials (Carbon Steel, Stainless steel, Chromoly, Bronze, Cast iron, Plastics)

Threading of all sizes and pitches (60 degree, Acme, Square, API, Buttress, NPT & NPS)

Milling & drilling

Broaching

Water lube pump parts

Some of the things we do regularly are:

Fabrication of pump shafting (Line shaft, Head shaft, bowl shaft, Split case, etc,)

Fabrication of pump oil tubes and tube specials (Johnston, Peerless, Winthrough, Flowserve, etc.)

Repair of booster, mixed flow, and horizontal pumps.

Fabrication of bushings, wear rings, and spacers

Fabrication of internal/external key ways

Fabrication of Pin/box sub connectors

Restoration of sheaves and fly wheels

From simple repairs, creating new parts from scratch, fabrication or from blueprint, KP Ventures’ Machinist can do it. When you can’t wait on a part for your water well, call KP Ventures. We’ll make the part and install it too. Call us today.

Bowl Repair & Replacement

Bowl Replacement and Repair

If you are experiencing any of the following, then you may need to consider repairing or replacing your pump bowls:

Pump or motor cavitation or vibration,

Bowls, impellers or other parts of your pump system are showing signs of corrosion,

Castings require material upgrades,

Changes within the overall pump system result in the pump no longer meeting hydraulic demands,

Excessive maintenance is required.

If you’d like to consider the options for repairing or replacing your pump bowls, call our pump experts to help repair or replace individual components. We understand these systems are expensive and will do everything in our power to extend the life of an existing pump.

In instances where vertical turbine pump bowls or impellers are irreparably damaged, the pump can experience vibration and decreased performance. A new bowl or portion thereof presents an economical solution to extend the lifespan of aging vertical turbine pumps and pump components.